Cooling in Data Centre

When you turn on your TV at your home and after some time when you put your hands at the back of the TV you'll feel warm air coming out. This is due to the energy being created inside the TV is transferred into heat, making the device feel hot but this will not be the case in the front face of your TV screen as there won't be any space for the hot air to come out but yes the TV which we get nowadays in the market has space just below the screen to escape the hot air from the TV which otherwise would heat the TV when used prolonged and thus increasing the risk of damaging the TV. The same is the case in Data Centre also.

The Data Centre is a building with a large number of IT devices placed the stack in a tall box-like structure called Rack. The devices are kept in a rack such that the front face of all the devices is facing the same direction as the backside in the other direction. The front face side of the rack is called a Cold Aisle where the cold air from the AHU comes to the rack whereas the backside of the rack is called a Hot Aisle where there is heat generated by the devices which will go back to the AHU through the Damper filter. This is done to maintain the temperature in the Racks. Since the devices are placed in a stack of huge numbers we can now imagine the amount of heat produced by the devices which not maintained in parameters leads to serious damage to the health of the devices, so to maintain the temperature in the server hall (a hall where large numbers of racks are installed) we use PAC (Precision Air Conditioning) Unit or AHU (Air Handling Unit). The PAC or AHU alone cannot control the room temperature unless it is not operated along with Chillers. Now let us see What PAC or AHU and Chillers are and how do they work together.

|

| Hot Aisle - Cold Aisle Approach inside a server room |

Precision Air Conditioning (PAC), also known as CRAC (Computer Room Air Conditioner) or CCU (closed Control Unit) is a system that is designed to run for long hours, unlike some commercial air conditioners. It is termed Precision as it provides precise control of temperature and humidity in all applications in which is required a very high degree of precision.

A chiller is a machine that provides chilled water to AHU or PAC for air conditioning in industrial buildings. The water coming out from the chiller is chilled with the help of a refrigerant which goes through a cycle called the refrigerant cycle.

Basically, there are two types of a chiller.

- Air Cooled Chiller

- Water Cooled Chiller

A water-cooled chiller operates water reservoir circulation while the air chillers disperse heat using fans. Both air-cooled and water-cooled chillers depend on the air stream for heat transfer. The air-cooled chillers use the environmental air while the water-cooled chillers depend on the air stream paired with water. Water-cooled chillers are usually located in the basement of the building whereas the air-cooled chillers are located on the rooftop.

Working of a Chiller

Chillers work on the principle of

1. Phase Change

A liquid coolant undergoes a phase change into gaseous when heated and back to liquid when cooled down.

2.Heat Flow

Heat is a form of energy. It flows from high temperature to low temperature.

3.Boiling Point

Reducing the pressure over a liquid decreases its boiling point and increasing the pressure increases its boiling point.

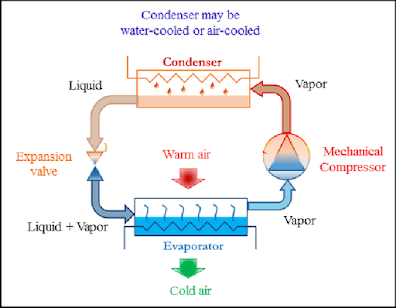

The chillers contain a refrigerant that chills the water. 4 different parts are working in the chillers simultaneously in the form of a cycle called the Refrigerant cycle. They are

1. Compressor

The cycle starts from the compressor where the compressor pumps the refrigerant in gaseous form from the evaporator and then compress it raising its temperature and pressure and pushes forward to the condenser.

2. Condenser

The high-pressure high-temperature refrigerant from the compressor now comes to the condenser where the temperature of the refrigerant is lowered with the desired pressure and then the low-temperature high-pressure refrigerant is pushed forward towards the expansion valve.

3. Expansion Valve

It is a device also called the throttle valve that reduces the refrigerant's pressure from high to low by passing through a narrow hole space, thereby reducing the temperature of the refrigerant still further. Now the refrigerant at its outlet is of low pressure and low temperature which is now pushed forward to Evaporator.

4. Evaporator

An evaporator is a place where the actual heat exchange takes place. The refrigerant from the expansion valve reaches the evaporator and cools the water. The refrigerant at its output is of normal pressure and temperature.

|

| Refrigeration Cycle |

The chilled water leaves the evaporator at around 6°C(48.2°F) is pushed around the building by the chilled water pump. The Chilled water now flows up/down, according to the type of chiller used i.e. it goes up if the chiller used is water type as water type chillers are mainly located in the basement of the building whereas the Air type chiller is placed on the roof of the building so the water goes downwards to the AHU. The Pipe which takes chilled water from the evaporator is called Riser no matter the direction it flows.

|

| schematic of a chiller |

The chilled water branches off the risers into small diameter pipers that take the chilled water to the AHU's (Air Handling Unit) to provide air conditioning. The AHU's are box tall box-like structures with fans inside that suck air from the building and push it across the heating or cooling coils to change the temperature of the air and then push this air back to the building. The chilled water enters the AHU and passes through a series of cooling coils which will absorb the heat of the air blowing across. The chilled water heats up and the air blowing across it cools down. when the chilled water leaves the cooling coil of the AHU, the water now will be warmer at about 12°C (53.6°F) and it heads back to the chiller in the evaporator and the unwanted heat will be transferred to the condenser via a refrigerant loop. The Condenser absorbs this heat and dumps it into a water condenser loop between the cooling tower and condenser. The cooling tower now forces the ambient air across the condenser water to extract unwanted heat and the fan in the cooling tower will force this heat to leave in the atmosphere and again the refrigerant cycle starts and this process continues until the chillers are turned off.

Comments

Post a Comment